LJ-4000 whole egg washing machine production line is composed of egg loading water tank,washing&drying,candling and egg breaking. 1. Equipment model and parameters The LJ-QQ4...

LJ-4000 whole egg washing machine production line is composed of egg loading water tank,washing&drying,candling and egg breaking.

1. Equipment model and parameters

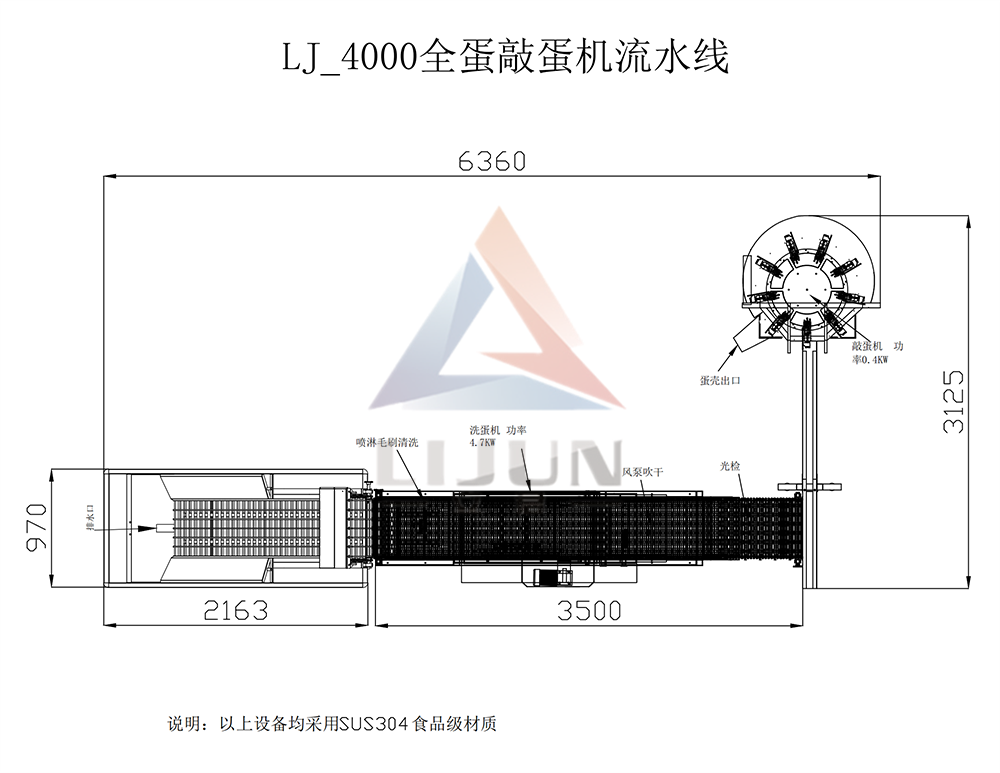

The LJ-QQ4 production line consists of an egg loading water tank, cleaning and air drying (optical inspection), and a 9-claw full egg liquid knocker. Its main technical parameters are as follows:

Maximum processing capacity: 4000 pieces/hour

Power supply: 380V/50Hz

Power: 8kW

External dimensions: 6360mm x 3125mm x 1600mm

Material: SUS304

2. Equipment characteristics

High efficiency: The device can process 4000 eggs per hour, greatly improving cleaning efficiency and reducing labor and time costs.

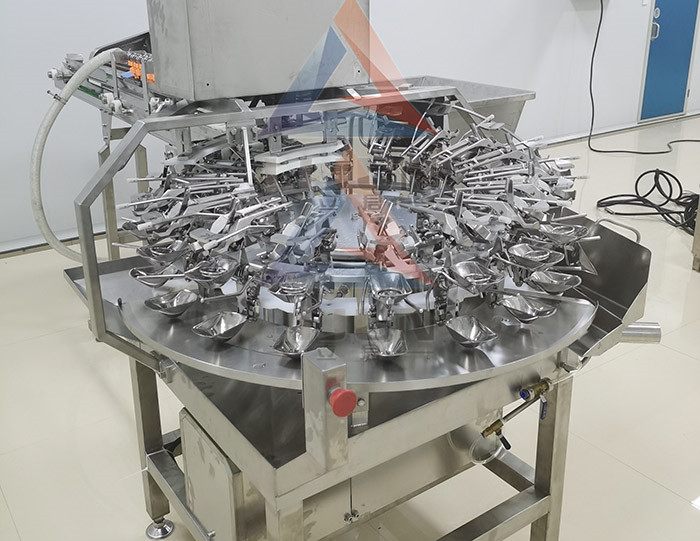

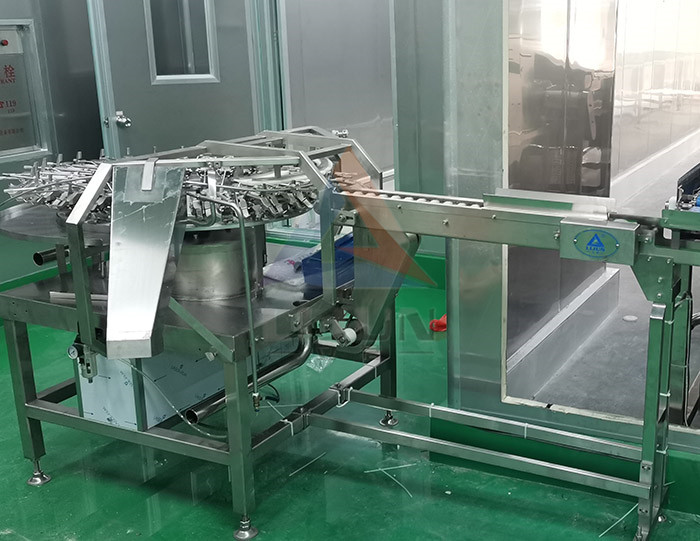

High degree of automation: The equipment is equipped with an egg loading water tank, an egg washing machine, a 9-claw egg knocking machine, and other components, achieving automated functions such as automatic egg loading, efficient cleaning, and automatic egg knocking, reducing the difficulty of manual intervention and operation.

Cleaning and hygiene: The equipment uses a high-pressure nozzle to clean eggs, which can thoroughly clean the dirt on the surface of eggs and the gaps between eggshells, ensuring cleanliness and hygiene.

Safe and reliable: The equipment is equipped with safety devices such as leakage protectors and overheating protectors to ensure safe and reliable operation.

Easy maintenance: The equipment is designed reasonably, has a simple structure, and is convenient for daily maintenance and upkeep.