This production line is a complete set of fully automatic production lines, including: egg feeder, lifting conveyor, egg breaking machine (8 rows), CIP cleaning. Customer...

This production line is a complete set of fully automatic production lines, including: egg feeder, lifting conveyor, egg breaking machine (8 rows), CIP cleaning. Customers can also choose egg washer,UV-disinfection, centrifuge, filter, etc. according to their needs.

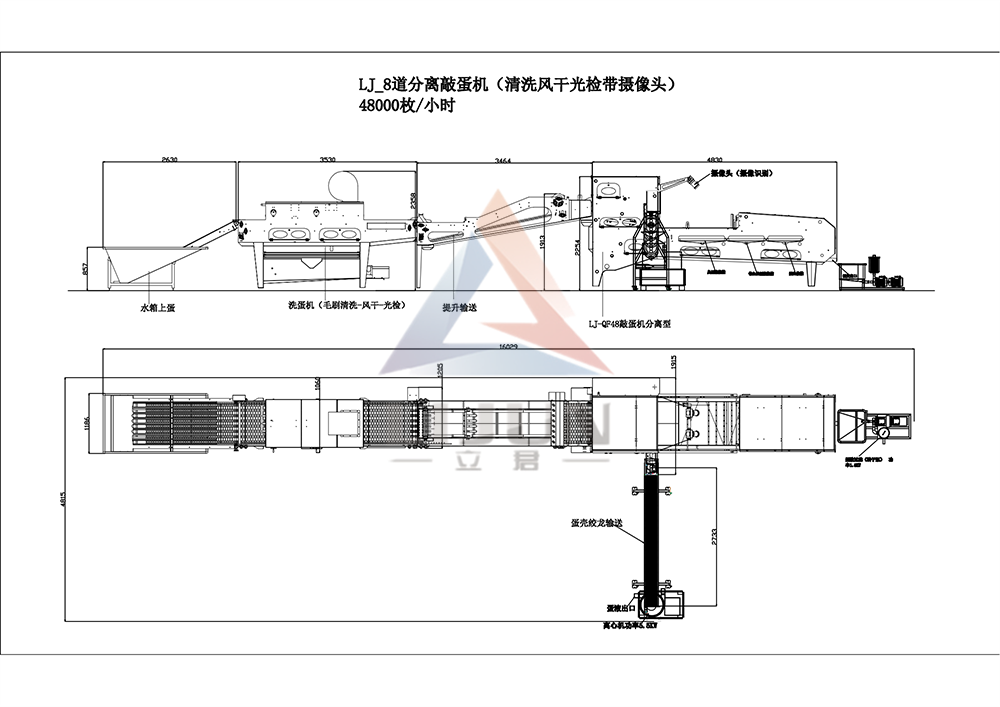

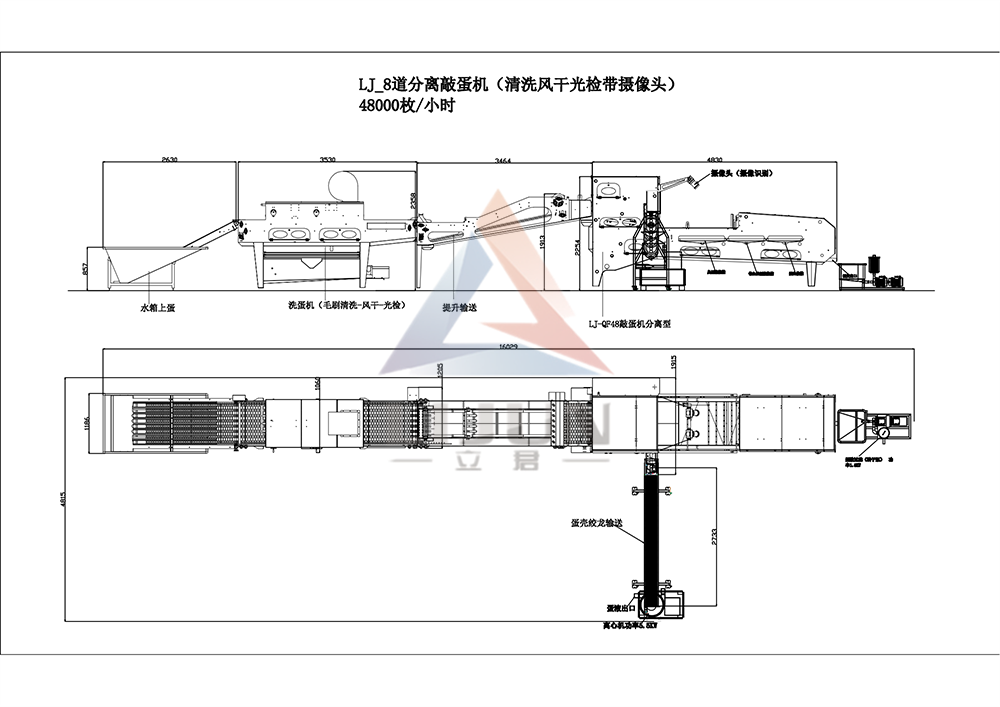

The production line is equipped with a special conveying system to transport eggs to the egg breaking machine. Its high performance is due to the use of first-class innovative egg breaking machines. This model is equipped with advanced solutions, a new human-machine interface that allows the operator to maximize the machine’s performance. Through the optimization of the gripper, egg cups, and camera recognition system, we have increased production capacity and product quality. Our egg breaker also uses a specially designed knife to break the eggshell, imitating the work of human hands.This most hygienic egg breaking method is an innovation of our LIJUN Machinery.

This commercial egg separation production line has an hourly capacity of 48,000~64,000 eggs.Once the eggs are broken,the egg falls into the egg cup, and the egg yolk and egg white are separated by the vibration of the egg cup,ensuring high-quality output for various cooking applications. The CIP cleaning system ensures that the egg cracking machine maintains the highest cleanliness and food safety standards.

This 5-rows separation egg breaking production line is suitable for medium-sized production enterprises, such as bakeries, liquid egg factories, egg powder factories, pharmaceutical factories, pasta factories, etc.

| Capacity: 48,000~64,000 eggs/hour Replaces: 96 people Power supply: 380V/50Hz 3phase Power: 14kw Water: from client’s installation Dimensions: 16029 * 2254 * 1915 mm Operated by: 1-2 persons |